Vietnam

Vietnam

Product Overview

Designed for fruits, vegetables, spices and food processing.

22This continuous mesh belt dryer provides uniform low-temperature drying with high throughput. Hygienic structure and stainless options make it suitable for food applications.

Technical Specifications

All parameters reflect strict ISO standards. Final throughput (kg/h) depends on material moisture and density.

222222

| Specification | JL-2×7 | JL-2×10 | JL-2×20 |

|---|---|---|---|

| Model | JL-2×7 | JL-2×10 | JL-2×20 |

| Drying Area (m²) | 70 | 100 | 200 |

| Belt Width | 2 m (Consistent Standard) | ||

| Layer Numbers | 5 / 6 / 7 (Optional) | ||

| Shell Insulation Thickness | 50 mm (High‑insulation standard) | ||

| Running Speed (m/min) | 0.4 – 4 (Fully adjustable) | ||

| Loading Capacity (kg/m²) | 10 – 40 (By material density) | ||

Standard Engineering & Flexibility

- Heat Source:: Biomass / Gas / Electric / Steam (Customizable)

- Shell Insulation:: 50 mm High‑Density Rock Wool (Consistent)

- Loading Range:: 10–40 kg/m²

- Material Grade:: SUS304 / SUS316 (Food Contact Parts)

- Temperature Range:: 40°C – 140°C

- Control System:: PLC Automatic Control (Local Language Optional)

Core Features

Engineered for hygienic, uniform and energy-efficient drying.

Compliance & Documentation

Audit-ready documents and drawings for installation and operation.

Service & Warranty

Our commitment: worry‑free service & long‑term partnership for SEA customers.

Ready to secure your machine’s future?

Working Principle

Layer-by-layer residence time + uniform crossflow + closed-loop dehumidification.

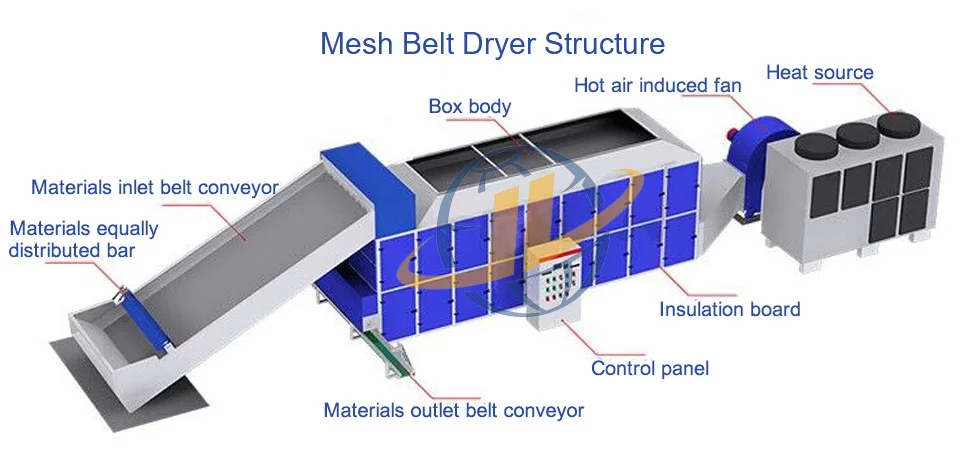

Structure Diagram

Inside the excellence: key components & engineering detail.

-

1

22Food Grade SUS304 Belt

(Hygiene First) All food‑contact parts use stainless steel, meeting HACCP requirements for export.

-

2

Versatile Heat Exchanger

(Fuel Flexibility) Works with biomass, gas or steam to match local energy prices and availability.

-

3

Modular Chamber Design

(Quick Setup) Pre‑assembled modules enable rapid on‑site installation, cutting labor and downtime.

-

4

Precision Control System

(Reliability) Siemens/Schneider‑grade components, digital HMI, and multilingual UI.

Material Compatibility

Optimized for Southeast Asian applications with focus on quality (fruits) and throughput (cassava/biomass).

Advantages vs Traditional Drying

Why upgrade to a Mesh Belt Dryer? Beat the rainy season & boost your production capacity.

| Feature | Sun Drying | Static Batch Oven | Mesh Belt Dryer |

|---|---|---|---|

| Weather Dependency | High risk — rainy season/night halt | Low — works anytime, but slow loading | Zero risk — 24/7 continuous |

| Hygiene & Safety | Poor — dust, flies, insects | Medium — manual contamination risk | Excellent — closed, food‑grade mesh |

| Labor Cost | High — flipping/moving by hand | Medium/High — tray loading/unloading | Low — auto feeding & discharge |

| Drying Quality | Uneven — hard to control color/moisture | Inconsistent — top/bottom trays differ | Uniform — good‑dry rate ≈ 96–98% (by material) |

| Capacity | Limited by space | Small batch | Large‑scale (200–3000 kg/h, custom) |

222222

Optional Configurations & Customization

Tailor the machine to fit your specific material, energy resources, and budget.

- Electric — clean and easy to control; ideal for high hygiene.

- Natural Gas / LPG — fast heating, cost‑effective in urban zones.

- Biomass / Wood / Coal — highly recommended for SEA rural areas; supports rice husks, wood chips, palm shells.

- Steam / Thermal Oil — best if your factory has a central boiler.

- Standard — contact parts SUS304; frame carbon steel with anti‑rust paint (most popular).

- Premium — full SUS304 for HACCP/GMP, seafood/corrosive or high humidity.

- Industrial — full carbon steel for non‑food (briquettes, sludge, minerals).

- Stainless Wire Mesh — standard for vegetables and herbs; good airflow.

- Teflon Anti‑Stick Mesh — must‑have for sugary fruits (mango, pineapple, banana).

- Chain/Perforated Plate — for heavy or large materials (briquettes, cassava chunks, mineral balls).

- Button Panel — simple, durable, low maintenance.

- PLC + Touch Screen — precise temp/RH, recipe storage (e.g., Mango/Chilli), data logging; English/Vietnamese/Thai UI.

- Dehumidification System — faster moisture removal; critical for tropical climates.

- CIP System — internal spray nozzles for easy cleaning of the belt.

- Automatic Spreader/Feeder — ensures even layer thickness for uniform drying.

Installation Layout & Dimensions

Modular design for easy container shipping and quick assembly in your factory.

| Model | Processing Area | Rec. Factory Height | Machine Dimensions (L×W×H) | Loading |

|---|---|---|---|---|

| Small (GW-6M) | 20m × 6m | 4.5m | 8.5m × 2.2m × 2.8m | 1 × 40HQ |

| Medium (GW-10M) | 30m × 7m | 5m | 12.5m × 2.2m × 2.8m | 1 × 40HQ |

| Large (GW-12M) | 40m × 8m | 6m | 14.5m × 2.5m × 3.2m | 2 × 40HQ |

Live Operation: Automatic Mango Drying

Watch how we turn fresh mango slices into premium soft‑dried products without sticking.

-

0:00

Uniform Feeding (均匀进料) Auto‑spreader lays every slice flat and even.

-

2:22

Teflon Mesh Belt (特氟龙防粘) Designed for sugary fruits — zero sticking, easy cleaning.

-

5:40

Golden Color (金黄出料) Precise temperature control preserves color and texture.

Customer Case Studies

Trusted by many factories — real stories, real results.

Vietnam

Vietnam

Indonesia

Indonesia

Thailand

Thailand

FAQ

Everything you need to know about shipping, installation, and warranty in Southeast Asia.

Not necessarily. Our Mesh Belt Dryer features a modular design. ~80% of the machine is pre-assembled. We provide comprehensive video tutorials and 24/7 WhatsApp support.

Most clients in Southeast Asia finish installation in 3–5 days with their local team. This saves you $2,000+ in travel costs.

It depends on your capacity and heat source. For the lowest cost in SEA, we recommend using Biomass (Wood chips / Palm shell).

We offer a 12‑month warranty on the whole machine. Additionally, we ship a FREE Spare Parts Kit (worth $500) with the dryer, ensuring you have replacements for urgent needs.